9 Bench Grinder Attachments: Tried, Tested & Explained

With the right equipment you can multiply the jobs you can do with a bench grinder. Or you can make your bench grinder safer to use. It all depends on the type of attachments you use. You do not have to limit yourself to just using your bench grinder to sharpen your tools.

Do bench grinders have attachments? Yes, they do. These attachments make your bench grinder even more versatile. Also, they help keep your bench grinder at its lofty status of being the most important tool in your tool collection.

To find about these different attachments and how to use them, just continue to read our article. We have done the hard work for you and found the information you need to know.

Different Bench Grinder Attachments and Their Function

1. Belt Sander

It is possible for you to turn your bench grinder into a belt sander. All you have to do is remove the right-hand wheel and replace it with the belt sander attachment. These attachments come in a variety of sizes, usually 2 to 4 inches wide by 36 or 48 inches long.

Then you can get up to 4 different grit styles to handle all your grinding and sanding needs. On top of having a belt, these bench grinder belt sander attachments also come with a7 inch disk. Your sanding options are unlimited when you find the right attachment to do the job.

Another good aspect to this attachment is that they are compatible with most bench grinders on sale now. Just check the owner’s manual before you make your purchase to see if it will fit your bench grinder.

While it keeps your bench grinding duties stable and in one place, their cost may not be budget friendly.

2. Polishing

When it comes to polishing on a bench grinder, all you have to do is remove one of the grinding wheels and replace it with a polishing wheel. The process is the same as replacing a normal grinding wheel with another normal grinding wheel.

Just make sure you get the right-sized arbor or you will have to make another trip to the store and get the correct one. The polishing wheel works best on lower speed bench presses and gives you more control over what you are doing.

The key is not to let your self be distracted and not to let your eyes wander. Keep your eyes on the wheel and the object you are polishing and keep your concentration on what you are doing.

The polishing attachment is not that elaborate and one tip you may find useful is that you may want to use an extender to help you polish correctly. An extender helps give you more room to maneuver making it easier to bring your object to a beautiful shine.

3. Buffing

When you want to do a little buffing on your metal objects, it is not that hard to do. The key is to get the right wheel to handle all the buffing duties. Like polishing, the buffing wheel is the bench grinder attachment.

Changing the wheel is the same as changing the grinding wheel and as described in the polishing section. When you use the buffing wheel, you do not want to use top speeds. If you have a variable speed bench grinder, then the lower speeds give you the best results.

Also, you will want to remove all the guards and tool rest before you buff. With those items attached, you will not have enough room to do a good job of buffing. It is possible to use a larger sized buffing wheel on a 6 or 8 inch bench grinder. You may need to buy and use an adapter to make it fit right and still give you room to work.

4. Dust Collector

It is possible to get a dist collection system to handle all the fine metal dust you are producing as you grind. Some of these systems are quite large and work with 7 and 10inch bench grinders.

They also can be quite expensive to buy. Plus, you will have to take the time to set it up properly before it makes your bench grinding life easier. Regular 6 and 8-inch bench grinders come with built-in dust ports that allow you to attach dust collection systems.

Dewalt does make a dust controller that has a universal hose fitting. It should work on most bench grinders and help you keep the dust down in your shop. The cost will range depending on the model and style you choose to use.

Most of the dust controllers are made for the angle grinder and not the bench grinder. They are very cost effective and protect you from rising dust.

5. Drums

There are a variety of drum sanders that you can buy and attach to your bench grinder. They should replace the right side grinding wheel if you want the best results and not damage your bench grinder.

It is possible that you may require an adapter to make sure the arbor fits snugly in with your arbor size. A flex shaft gives you lost of room to maneuver as well as moving the drum sander out a couple of feet from the bench grinder.

They also come in a variety of grit sizes starting at 80 and going on up to 220. Rubber sanding drums may also still be available but you may have to look long and hard to find any today.

Each drum sander varies in size and you will just need to find the one that fits with your bench grinder while still giving you ample room to maneuver your object.

6. Linisher

Linishers are small and thin sanding belts that easily attach to your bench grinder. They can be placed on either side of the grinder and can be set in a variety of positions.

These attachments polish a variety of items but due to their small size, you do not want to try and polish wide or long items. They will also smooth off a variety of surfaces protecting your hands from any burrs or knicks, and so on.

The linisher just slips on to your bench grinder as long as the arbor and spindle measurements line up. No matter which hand is the dominate one, you can place the linisher on your bench grinder to favor that hand.

Plus, you are not stuck with just one grit size. You should be able to find linisher belts in a variety of grit sizes that will enhance your polishing work. You can fine tune your project and even get the smaller pieces nice and polished.

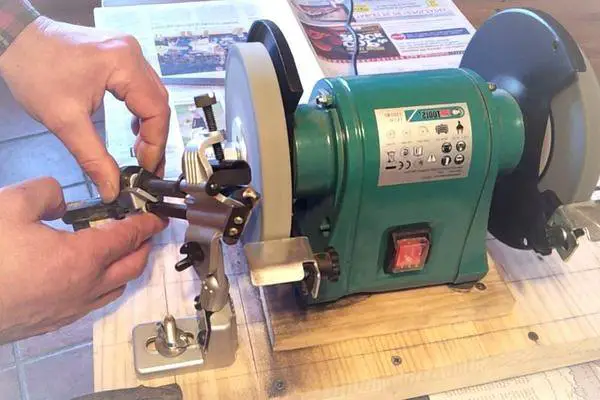

7. Spindle

One of the good aspects of this bench grinder attachment is that you can get a spindle adapter for either side of your grinder. It doesn’t matter where you are grinding you can use these spindle adapters with ease.

After you remove the grinding wheel, you attach the spindle by its grub screws. To attach it to your bench grinder, you will need to remove the grinding wheel and the inner and outer guards. Then the spindle fits right into place.

This attachment is necessary if you want to use your bench grinder as a polisher. Also, you can use the spindle as an extender. These spindles come in various sizes and can give you 4, 6 or more inches of room to run your different specialty grinding wheels.

Spindles are safe to use and they give you more grinding or polishing options.

8. Drill Chuck

Mounting a standard drill chuck to your bench grinder is an impossible task. The too items are just not compatible,. But there is a simple solution. You can attach a flex hose drill chuck to your bench grinder or drill press.

The flex hose chuck comes with a PVC handle, attaches to rotary tools in seconds and gives you enough length to reach those hard to reach places you need to work on.

Along with grinding, these tools are great for sanding, dust removal, fine polishing and more tasks.

Plus, they are lightweight, easy to maneuver and can be used for long periods of time. Their flexible nature lets you bend them into the position you need at the time. You can even go around corners with them.

Instead of using a drill chuck, opt for one of these multi task flex hoses that works well with a bench grinder.

9. Bench Grinder Stand

This is a must-have bench grinder attachment. These stands are well made, strong and can easily be moved from one location to another. Plus, they can come with a tool tray so you do not have to stop and look for the toll you need. It will be right there waiting for you.

Each stand comes in a different size and shape but they will keep your bench grinder at the level you need to work comfortably. They are also easy to assemble and come with enough attachment holes to keep your bench grinder in place.

Some even come with wheels so you can move your bench grinder where you need it next quickly and without hassle. In addition to all of this, their weight capacity should make them strong enough to handle most bench grinders, even those with cast iron bases.

With their adjustable nature, you can always change your grinding position when you get tired or your muscles get sore. A bench grinder stand is the perfect attachment to have when you do not want to stay in one spot to do all your grinding.

What to Look for in Buying an Attachment

Knowing what to look for will save you a lot of time and possibly a lot of money. You want to make sure you get the right attachment for the bench grinder you own. Here are some characteristics to look for when searching for the right attachment:

- Compatibility - not all attachments have a universal fit., You have got to make sure the attachment will fit your bench grinder and work safely.

- Belt sizes - when using a linisher or sander attachment, check the belt sizes you need. Plus, look at the grit strengths. You want the right belt that will hold up and fit on the attachments.

- Capability - for example are the dust collectors that are available for bench grinders, can they do the job and do it well? The same goes for all attachments, you do not want an inferior product on your bench grinder as that can lead to many issues later on.

- Wheels - you want to make sure the polishing and buffering wheels will match up with your bench grinder. They need to match the arbor size plus the speed of the grinder.

- Extension - will the attachment provide you with the right amount of extra length you need to make sure the other attachments work without interference.

- Quality of construction - again you do not want an inferior made attachment. This will only cost you more money to replace it when it breaks or does not work properly.

- Stability - this pertains to bench grinder stands and you need to have a stable stand if you are going to get your work done right.

- Height - again this applies to the stand, It should be adjustable and have a fair-sized height range. Also, its platform should be large enough to hold your bench grinder with ease.

Some Final Comments

Bench grinders do more than sharpen tools. With the right attachments, you can expand your bench grinder’s contribution to your workshop and projects. Having a stationary belt sander that can grind at the same time is an enormous plus to any working situation.

Then when you get the right wheels, you can save time by doing your polishing and buffering yourself. They say ‘if you want a job done right, do it yourself.’ and bench grinding attachments help you do just that.

Of course, not all bench grinding attachments will fit your hobby or grinding duties. Just pick up those items that fit in well with what you do in your spare time. The key is to know what you are looking for and how to use it correctly.